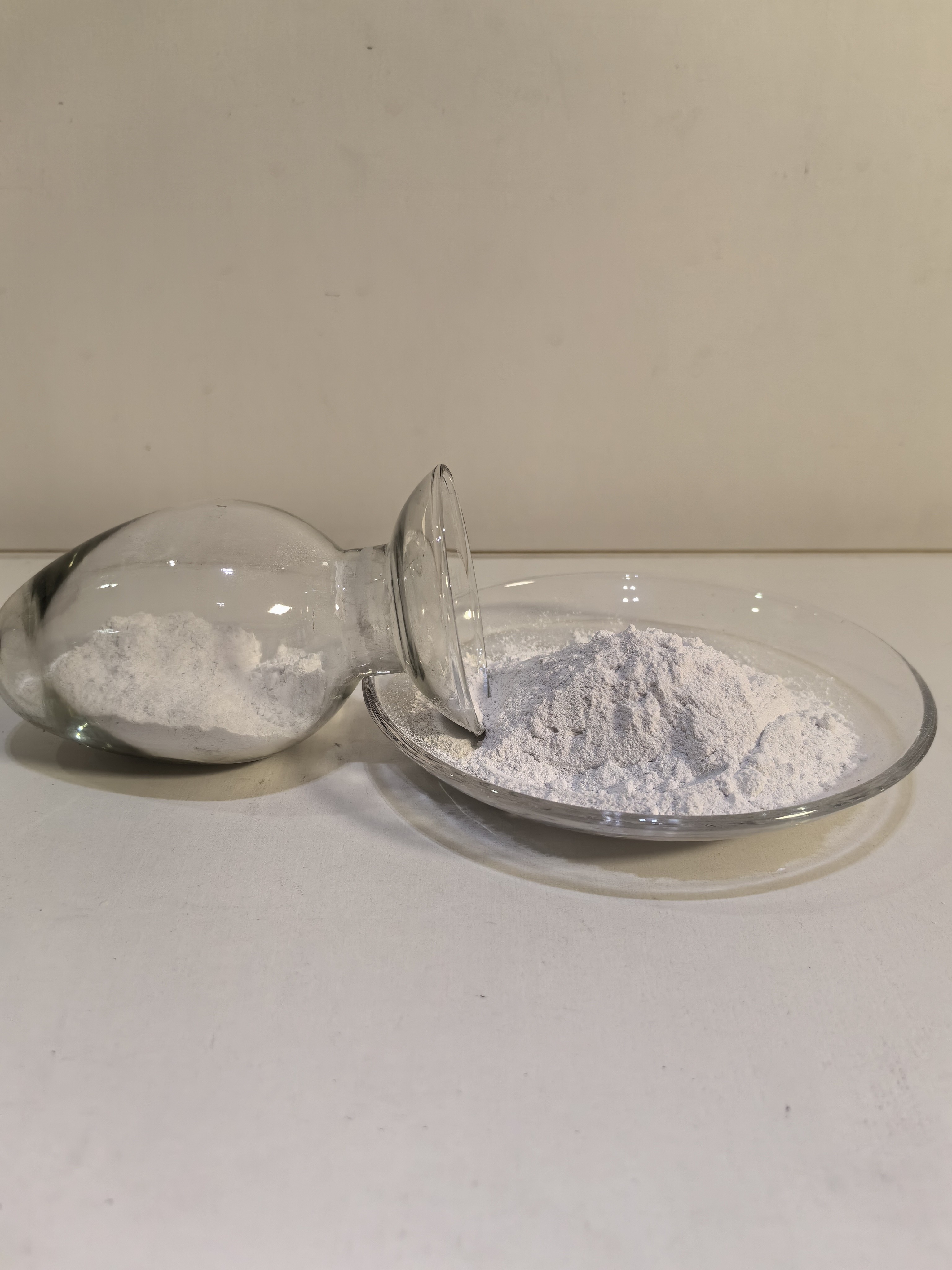

85% Semi-encrypted Silica Fume 85% Semi-encrypted Silica Fume, is a byproduct of the production of silicon and ferrosilicon alloys. It is a highly reactive pozzolan with a high silica content of over 85% and a bulk density of around 300 kg/m3. The specific surface area of 85% Densified Silica Fume is very high, ranging from 15,000 to 30,000 m2/kg, making it an ideal supplementary cementitious material for enhancing the strength, durability, and workability of concrete. 85% Semi-encrypted Silica Fume, 85% Semi-encrypted Silica Ash, 85% Semi-encrypted Silica Powder Chengdu Rongjian Engineering Materials Co.Ltd , https://www.rjsilicafume.com

Brief introduction to the working principle of water ring vacuum pump

Water ring vacuum pump works Description: Water ring vacuum pump (water ring pump) is a rough vacuum pump, it can get the ultimate vacuum of 2000 ~ 4000Pa, series of air ejectors up to 270 ~ 670Pa. Water ring pump can also be used as a compressor, called the water ring compressor, is a low pressure compressor, the pressure range of 1 ~ 2 × 105Pa gauge pressure. In the working principle of the water ring vacuum pump, water ring pump was originally used as a self-priming pump, and then gradually used in many industrial sectors such as petroleum, chemical, machinery, mining, light industry, medicine and foodstuffs. In many industrial processes, such as vacuum filtration, vacuum water diversion, vacuum feed, vacuum evaporation, vacuum concentration, vacuum resurgence and vacuum degassing, water ring pump is widely used. Due to the rapid development of vacuum application technology, water ring pumps have gained much attention in the area of ​​rough vacuum. As the water ring pump gas compression is isothermal, it can be extracted flammable and explosive gases, in addition to pumping dust, water-containing gas, therefore, water ring pump applications are increasing. In the pump body with the right amount of water as a working fluid. When the impeller rotates clockwise in the figure, the water is thrown around by the impeller. Due to the centrifugal force, the water forms a closed ring of approximately equal thickness depending on the shape of the pump chamber. The inner surface of the lower part of the water ring is just tangential to the hub of the impeller. The upper inner surface of the water ring is just in contact with the top of the blade (in fact, the blade has a certain insertion depth in the water ring). At this moment, a crescent-shaped space is formed between the impeller hub and the water ring, and the space is divided into a plurality of small cavities equal to the number of the blades by the impeller. If the lower part of the impeller 0 ° as a starting point, then the impeller 180 ° before rotation when the small chamber volume from small to large, and the end of the suction port communicating, when the gas is inhaled, when the inhalation end of the small cavity When the impeller continues to rotate, the small cavity becomes smaller and the gas is compressed; when the small chamber communicates with the exhaust port, the gas is discharged outside the pump. In summary, water ring vacuum pump working principle is based on changes in pump chamber volume to achieve suction, compression and exhaust, so it belongs to the varactor vacuum pump.

85% Semi-encrypted Silica Fume (85D) is a type of silica fume that has been processed to increase its bulk density. This makes it easier to handle and transport, and can also improve its performance in concrete.